兵庫県尼崎市 精密研削・研磨専門メーカー 平井工業株式会社

![]()

![]()

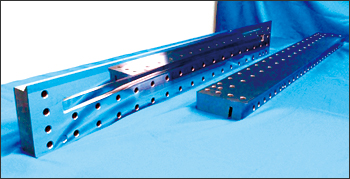

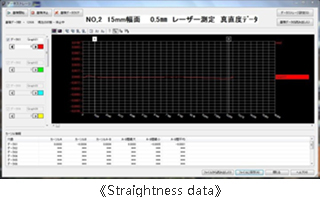

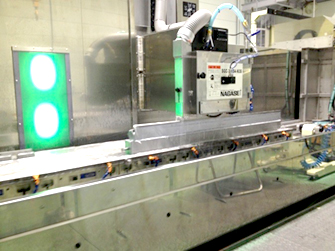

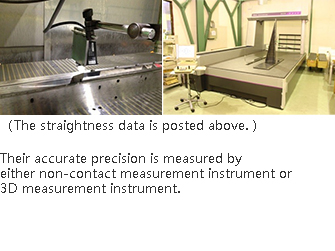

Our 25 years of experience in HIP LIP manufacturing has evolved into T-dies, round dies, granulation and extrusion dies. And now, introduction of the ultra-precision mirror surface grinding machine enabled us to manufacture HIP coating dies with straightness of 1μ/M.

|

|

![]()

“HIP LIP” was developed in effort to reduce the “die drool.” They reduced the “die drool” to one third from the before and have earned trust from their users. In pellet granulation, data proving the reduction of defects attributed to “die drool” was produced. In “coating die,” significantly extended operating time with the liquid containing the “filler” has been confirmed, and has been attracting attention from the battery manufacturing in the energy sector.

![]()

|

|

![]()

The true advantage of the HIPcoating dies lies in the fact that they are productized in true aim of reducing the various issues users are facing, including the streaks and the discoloration at their storage after the cleaning. They are HIP alloyed at the sharp tip edge and across the whole flow channel.

![]()

|

|

![]()

HIP LIP has been productizing to fulfill the requirement of the users. The HIP hardness in some application has been increased from HRC58 to HRC60 or higher. Their surface roughness are available in Rz 0.2 μm or Ra 0.03 μm or lower. A critical factor, the needle position width are available in 5 μm or smaller, depending on the specification or application of the user.

HIP T-dies, lips, coating dies and other dies sized 2,000 mm or larger can be manufactured.

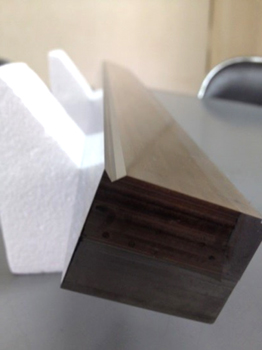

Because the HIP layers can be manufactured in order of millimeters, repair can be completed only with the “grinding.”

For repair process, try “HIP LIP” which provides low running costs and fast lead time.

![]()

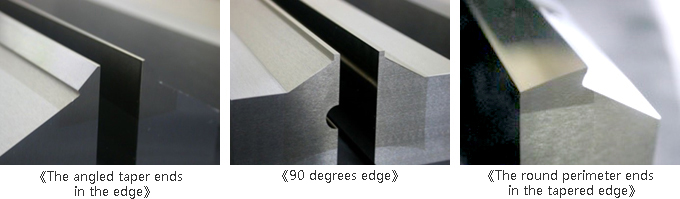

The shape machining profile distinctive to the HIP LIP

|

![]()

|

Sufficient HIP layer ensures restoration to newly made condition. Even these kinds of edges can be manufactured: V-groove with line width of 10 micron millimeter or smaller can be manufactured. Rz 0.2μm of roughness. Because the HIP is tough, it will not have “chip” even if made into the edge similar to this. The work piece test machined in the manufacturing of 1,700 mm HIP LIP product. The shapes that are “difficult to make” by the surface treatment are available. Properties of nickel-system alloy: Ductile, hard, chip-resistant, wear-resistant and corrosion-resistant. |

![]()

We recommend our HIP LIP for manufacturing of T-dies, T-die lips, coating dies, round dies, pellet granulation, extrusion dies, air nozzles or other nozzles, or other high performance products related to the dies.

![]()

|

Contact us for HIP LIP * Regarding the requests for information or quotes from the oversea customers: |

経済産業省 平成26年度ふるさと名物応援事業補助金(地域間連携型新連携支援事業)